How Do Hydrogen Water Bottles Work?

Hydrogen water bottles are innovative devices designed to infuse water with molecular hydrogen, offering a convenient way to enjoy the potential health benefits of hydrogen-rich water. These bottles use advanced technology to generate and dissolve hydrogen gas directly into the water, creating a portable source of antioxidant-rich hydration. The unique properties of hydrogen water, including its potential to reduce oxidative stress and inflammation, have led to a growing demand for these bottles among health-conscious individuals.

The purpose of this post is to explain how hydrogen water bottles work, breaking down the key components and processes involved. Understanding these aspects will help you make an informed decision when choosing a hydrogen water bottle that meets your needs.

Key Components of a Hydrogen Water Bottle

Hydrogen water bottles are intricate devices designed to infuse water with molecular hydrogen (H₂), providing potential health benefits. Understanding the key components of these bottles is crucial to grasp how they function.

Electrolysis Chamber

The electrolysis chamber is the heart of a hydrogen water bottle. This chamber is where the water, typically H₂O, is split into its basic components: hydrogen (H₂) and oxygen (O₂). The process is straightforward. When the device is activated, an electric current passes through the water in the chamber. This current facilitates the breakdown of water molecules into hydrogen and oxygen gases.

The electrolysis chamber’s effectiveness directly impacts the hydrogen concentration in the water. A well-designed chamber will ensure the hydrogen gas is effectively separated and infused into the water, while the oxygen is either released or kept separate.

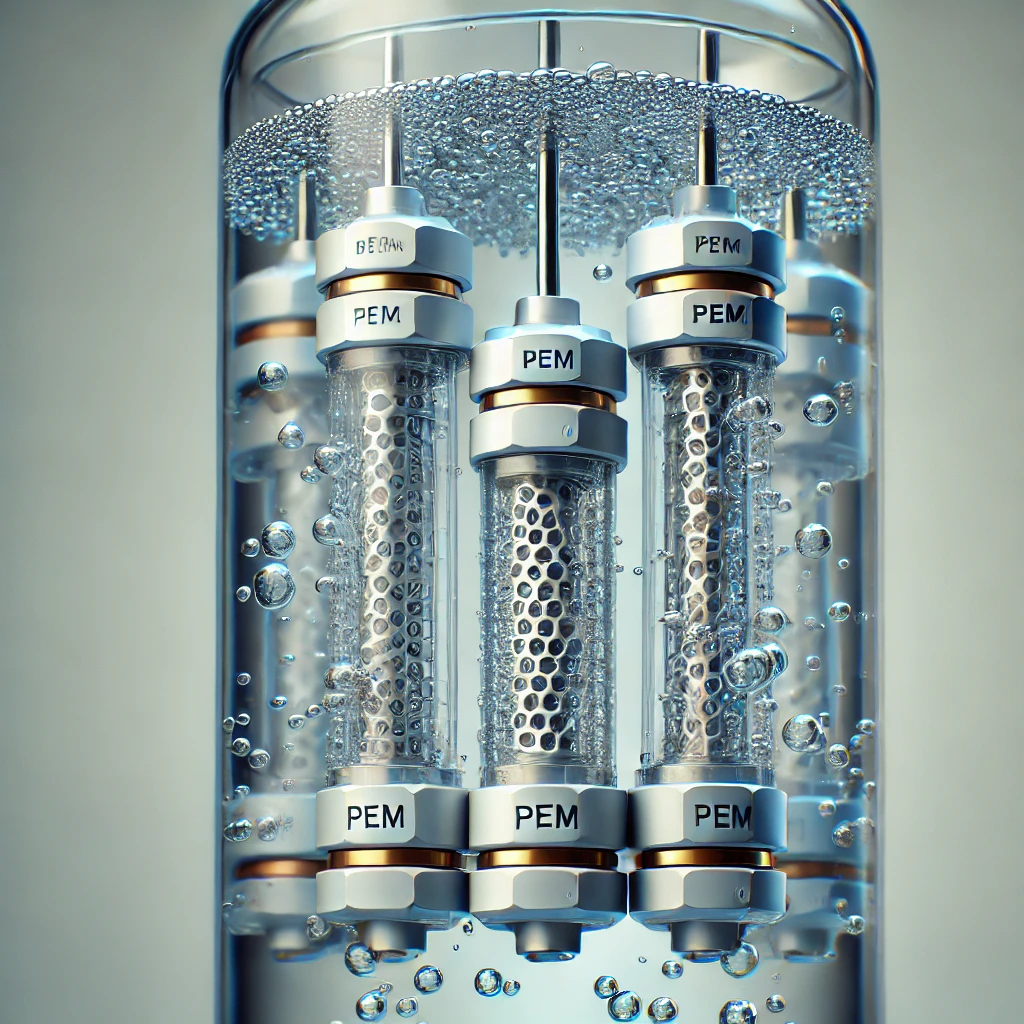

Proton Exchange Membrane (PEM) Technology

Proton Exchange Membrane (PEM) technology ensures that only pure hydrogen is produced during the electrolysis process. PEM acts as a selective barrier, allowing only protons (positively charged hydrogen ions) to pass through while blocking other ions and gases, such as oxygen.

This technology is critical because it prevents oxygen contamination in the hydrogen-rich water. By using PEM, the hydrogen water bottle ensures that the water you drink is infused with pure molecular hydrogen, enhancing its potential health benefits.

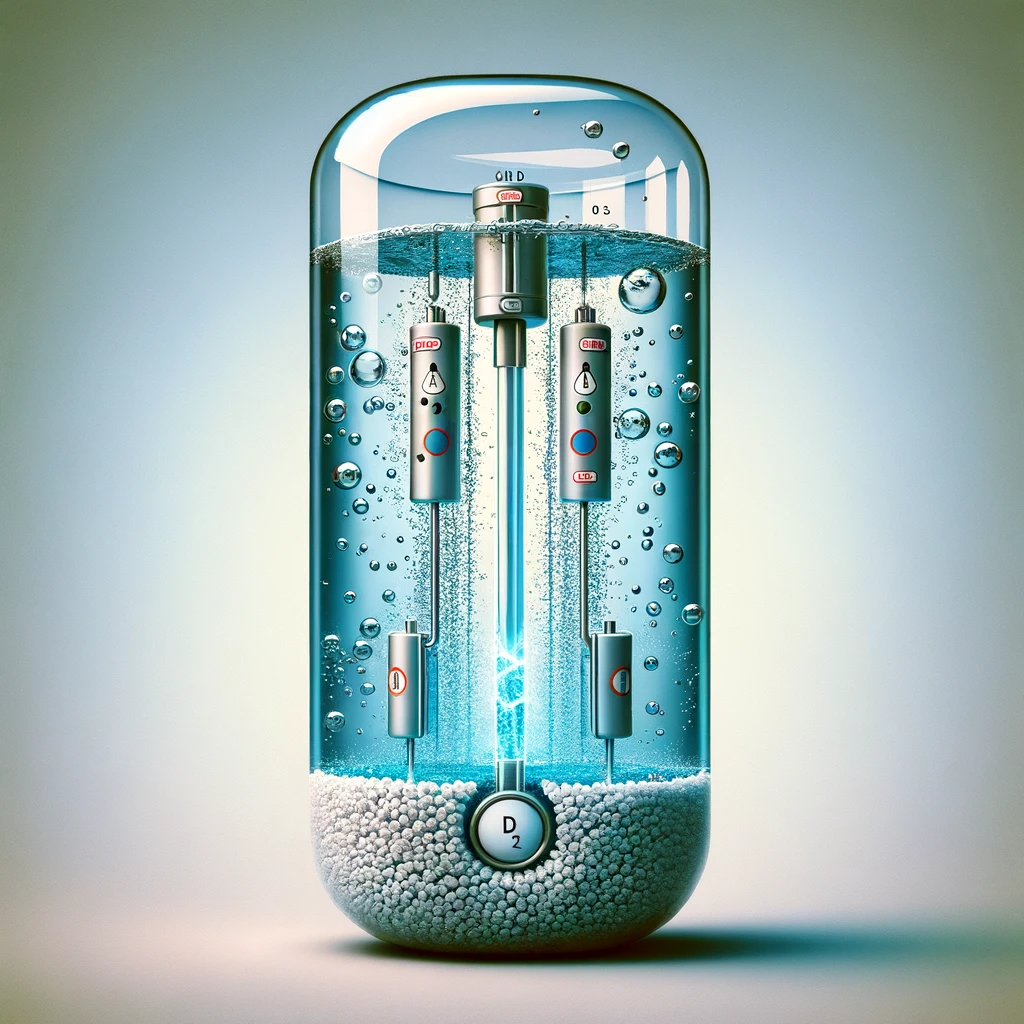

Electrodes

Electrodes play a crucial role in the electrolysis process. In a hydrogen water bottle, there are typically two electrodes: one positive (anode) and one negative (cathode). When the battery powers these electrodes, the electric current they produce splits the water into hydrogen and oxygen.

The positive electrode attracts negatively charged ions (anions), while the negative electrode attracts positively charged ions (cations). This movement of ions is what drives the separation of hydrogen and oxygen. The quality and durability of these electrodes directly affect the efficiency and longevity of the hydrogen generation process.

Water Reservoir

The water reservoir is the component where the water is stored before and after the hydrogen infusion process. It is typically made of materials that are resistant to corrosion and contamination, ensuring the purity of the water throughout the process.

The reservoir’s capacity can vary, but it usually holds enough water for multiple uses before needing to be refilled. After the electrolysis process, the hydrogen-infused water remains in the reservoir until it is consumed. A well-designed reservoir minimizes hydrogen escape, maintaining the concentration of hydrogen in the water for as long as possible.

Battery and Power Source

The battery is the power source that drives the electrolysis process. The efficiency and longevity of the hydrogen water bottle largely depend on the quality of its battery. A robust battery ensures that the electrolysis process is consistent and that the device can be used multiple times on a single charge.

Most hydrogen water bottles use rechargeable batteries, often charged via USB. The charging time and battery life are critical factors to consider, as they affect the device’s usability and convenience. A good battery will power the electrolysis process without significant drops in efficiency, ensuring that the water is infused with an optimal concentration of hydrogen every time.

The Electrolysis Process: How Hydrogen is Produced

The process of producing hydrogen in a water bottle involves several key steps. This section will break down the electrolysis process, the separation of gases, and the infusion of hydrogen into the water. Each step is crucial for ensuring that the water you drink is enriched with molecular hydrogen.

Understanding Water Electrolysis

Water electrolysis is the fundamental process behind hydrogen water bottles. In simple terms, electrolysis is the use of an electric current to split water (H₂O) into its two basic components: hydrogen (H₂) and oxygen (O₂).

When the device is activated, the battery sends an electric current through the water via the electrodes. The current causes a chemical reaction where water molecules are broken down into hydrogen and oxygen gases. The hydrogen ions (protons) migrate toward the negative electrode (cathode), while the oxygen ions move toward the positive electrode (anode). This separation is critical as it lays the groundwork for the next stages.

The efficiency of this process can be influenced by factors such as water quality, the duration of electrolysis, and the charge levels of the battery. High-quality water and an adequately charged battery ensure that the electrolysis process is both efficient and effective, producing a higher concentration of hydrogen.

Separation of Gases

Once the water is split into hydrogen and oxygen, the next challenge is to separate these gases effectively. In a hydrogen water bottle, this separation is achieved through the use of a Proton Exchange Membrane (PEM). The PEM only allows hydrogen ions to pass through it while blocking oxygen and other gases.

This selective permeability is crucial because it ensures that the water is infused only with pure hydrogen. The oxygen is typically released from the system or kept separate, depending on the design of the bottle. By preventing oxygen contamination, the PEM enhances the purity of the hydrogen-infused water, making it more beneficial for consumption.

Effective gas separation not only ensures the purity of the hydrogen but also prevents potential issues related to oxygen buildup, which could compromise the safety and effectiveness of the bottle.

Hydrogen Infusion

After separating the hydrogen from oxygen, the final step is to infuse the hydrogen gas into the water. This process increases the hydrogen concentration in the water, making it “hydrogen-rich.”

The infusion process occurs within the water reservoir. Once the hydrogen gas is produced and separated, it is dissolved into the water stored in the bottle. The ability of the water to hold hydrogen depends on several factors, including the pressure and temperature inside the bottle. Higher pressure and lower temperature generally enhance the solubility of hydrogen in water.

Some hydrogen water bottles are equipped with indicators that show when the water has reached optimal hydrogen saturation. This feature is useful for ensuring that the water you consume has the highest possible concentration of molecular hydrogen, maximizing its potential health benefits.

How the Bottle Maintains Hydrogen Concentration

Preventing Hydrogen Escape

Hydrogen is the smallest molecule, making it prone to rapid escape from water. To address this, hydrogen water bottles are designed with several mechanisms to minimize hydrogen loss. The bottle’s sealing system is a primary defense. A tightly sealed lid and well-constructed bottle body ensure that hydrogen remains trapped within the water, preventing it from diffusing into the air.

In addition to a good seal, some bottles use specialized materials for the inner lining that reduce the permeability of hydrogen. This lining helps keep the hydrogen molecules in the water for a longer period, maintaining its concentration. These features are essential for users who want to consume hydrogen-rich water long after the electrolysis process has been completed.

Role of Pressure and Temperature

Pressure and temperature are key factors influencing the solubility and retention of hydrogen in water. Higher pressure inside the bottle increases hydrogen’s solubility, allowing more hydrogen to dissolve in the water. This is why some hydrogen water bottles are designed to withstand increased internal pressure, enhancing their ability to hold more hydrogen.

Temperature also plays a significant role. Cooler temperatures generally improve the retention of dissolved hydrogen, as warmer water allows hydrogen to escape more quickly. Some bottles are designed with insulation features to maintain a stable, cooler temperature, thus preserving the hydrogen concentration for a longer duration.

Understanding the relationship between pressure, temperature, and hydrogen solubility can help users optimize the hydrogen content in their water by storing and consuming it under the right conditions.

Indications of Hydrogen Saturation

Knowing when the water has reached optimal hydrogen saturation is vital for ensuring maximum benefits. Many hydrogen water bottles come with built-in indicators, such as LED lights or digital displays, to signal when the water is fully saturated with hydrogen.

These indicators typically activate when the electrolysis process is complete and the water has reached its peak hydrogen concentration. Some advanced models may even provide real-time monitoring of hydrogen levels, allowing users to track the concentration and consume the water at its most potent state.

These indicators serve as a practical tool for users, ensuring they drink the water when it is most beneficial, thereby maximizing the health advantages of hydrogen-rich water.

Factors Influencing the Efficiency of Hydrogen Generation

Water Quality

Water quality plays a crucial role in the effectiveness of hydrogen generation. Pure, clean water with low levels of impurities allows the electrolysis process to occur more efficiently. Tap water, which often contains minerals, chlorine, and other contaminants, can interfere with the electrolysis process, reducing the amount of hydrogen produced. For optimal results, it’s recommended to use distilled or filtered water in hydrogen water bottles.

High mineral content in the water, such as calcium and magnesium, can also lead to scaling on the electrodes, which decreases the efficiency of hydrogen production over time. Regular cleaning of the bottle and using high-quality water can help prevent this issue, ensuring consistent hydrogen generation.

Electrolysis Time

The duration of the electrolysis process directly affects the concentration of hydrogen in the water. Generally, the longer the electrolysis time, the more hydrogen is produced and dissolved in the water. However, there is a limit to this, as the water can only hold a certain amount of hydrogen before it reaches saturation.

Most hydrogen water bottles come with a preset electrolysis time optimized for typical water volumes. Users can adjust this time based on their preferences, but it’s important to avoid excessively long electrolysis sessions, as they can overburden the battery and diminish its lifespan without significantly increasing hydrogen concentration.

Battery Charge Levels

The efficiency of hydrogen production is closely tied to the battery’s charge level. A fully charged battery provides a consistent and strong current necessary for effective electrolysis. As the battery level decreases, the current weakens, potentially leading to reduced hydrogen generation.

To maintain optimal hydrogen production, users should regularly charge their hydrogen water bottle’s battery and avoid using the device when the battery is low. Regularly checking the battery level and charging it before it runs out can help ensure consistent performance and prolong the life of the bottle.

Environmental Conditions

External temperature and pressure also impact hydrogen water production. As mentioned earlier, cooler temperatures generally improve hydrogen solubility, while higher temperatures cause hydrogen to escape more quickly. Storing the bottle in a cool environment can help maintain hydrogen concentration.

Pressure plays a role in the electrolysis process as well. Higher internal pressure within the bottle enhances hydrogen solubility, making it easier for the water to retain hydrogen. Therefore, it’s beneficial to use bottles designed to withstand higher pressures, particularly in warmer climates where temperature control is more challenging.

Longevity and Maintenance of Hydrogen Water Bottles

Maintaining the longevity and performance of a hydrogen water bottle depends on the durability of its components and adherence to proper maintenance routines. Let’s explore how the quality of materials influences the bottle’s lifespan, the necessary maintenance tasks, and signs of potential wear and tear.

Durability of Components

The durability of a hydrogen water bottle is largely determined by the quality of its materials and components. High-grade materials, such as corrosion-resistant stainless steel for electrodes and durable polymers for the body, can significantly extend the life of the bottle. These materials are less prone to degradation, ensuring that the bottle can withstand repeated use over time without losing efficiency.

For example, Proton Exchange Membrane (PEM) technology used in many hydrogen water bottles relies on membranes that must be robust enough to handle the electrolysis process repeatedly without breaking down. High-quality PEMs maintain their effectiveness longer, reducing the frequency of replacements and overall maintenance costs. When selecting a hydrogen water bottle, it’s important to consider the quality of these critical components, as they directly influence the bottle’s lifespan and performance.

Maintenance Requirements

Regular maintenance is essential to ensure consistent hydrogen production and prolong the life of the bottle. One of the most important maintenance tasks is cleaning. Over time, mineral deposits and impurities from the water can accumulate on the electrodes and inside the chamber, reducing the efficiency of the electrolysis process. Regular cleaning, typically using a mild acid solution or a cleaning agent recommended by the manufacturer, can prevent buildup and keep the components functioning effectively.

Another key maintenance task is checking and replacing the battery. Since the battery powers the electrolysis process, keeping it in good condition is vital for consistent hydrogen generation. Regularly charging the battery and replacing it when it no longer holds a charge will help maintain the bottle’s performance.

Additionally, some bottles may require the replacement of specific components, such as filters or membranes, at regular intervals. Following the manufacturer’s guidelines for maintenance will ensure that the bottle continues to produce hydrogen-rich water effectively over time.

Potential Wear and Tear

Despite regular maintenance, components in a hydrogen water bottle can experience wear and tear over time. Common signs of wear include reduced hydrogen production, longer electrolysis times, and visible degradation of components like the electrodes or PEM membrane.

If the electrodes appear corroded or the PEM membrane shows signs of thinning or tearing, it may be time to replace these parts. Failing to address these signs can lead to a significant decrease in the bottle’s efficiency and potentially shorten its overall lifespan. Monitoring the performance of the bottle and being attentive to these indicators will help users address issues early, preventing more serious problems and maintaining the effectiveness of the hydrogen water bottle.

Safety Aspects of Using Hydrogen Water Bottles

Safety is paramount when using hydrogen water bottles, given the involvement of hydrogen gas and electrical components. Therefore, it’s important to understand the safe handling of hydrogen gas, the risks of overuse, and the importance of selecting bottles that meet recognized safety certifications and standards.

Handling of Hydrogen Gas

Hydrogen gas, while beneficial for health, is also highly flammable, which necessitates careful handling. In hydrogen water bottles, the amount of hydrogen gas generated is typically minimal and contained, reducing the risk of ignition. However, users should still follow safety guidelines to ensure safe usage.

Ensure that the bottle is used in well-ventilated areas to prevent any accumulation of hydrogen gas, especially during the electrolysis process. Avoid exposing the bottle to open flames or high heat sources, as these could increase the risk of combustion. Additionally, make sure that the bottle’s sealing mechanisms are intact to prevent any unintended release of hydrogen gas. Following these precautions can help minimize risks associated with hydrogen gas.

Overuse Risks

While hydrogen water bottles are designed for regular use, excessive or improper usage can pose risks. Overusing the bottle—such as running multiple electrolysis cycles back-to-back without allowing the device to cool down—can lead to overheating of the battery and other components, potentially causing damage or reducing the bottle’s lifespan.

Improper use, such as using water with high mineral content, can lead to scaling on the electrodes, which affects the efficiency of hydrogen production and may cause the device to malfunction. Users should adhere to the manufacturer’s instructions regarding usage frequency and water quality to avoid these issues. Ensuring that the bottle is used as intended will not only preserve its functionality but also safeguard the user from potential hazards.

Certifications and Standards

When choosing a hydrogen water bottle, it is crucial to select a product that meets recognized safety certifications and industry standards. Certifications such as CE (Conformité Européenne) and RoHS (Restriction of Hazardous Substances) indicate that the bottle has been tested and meets specific safety, health, and environmental protection requirements.

Using certified bottles ensures that the materials and components used are safe for contact with drinking water and that the device operates within safe parameters for electrical and hydrogen generation processes. Non-certified products may not provide the same level of safety assurance, potentially exposing users to risks from poor-quality materials or unsafe design.

To verify a bottle’s certifications, check the product documentation or the manufacturer’s website. Purchasing from reputable brands and suppliers can further ensure that you are getting a product that meets stringent safety standards.

Conclusion

Hydrogen water bottles use electrolysis to infuse water with molecular hydrogen, offering potential health benefits. Key components like the electrolysis chamber, PEM, and electrodes work together to efficiently generate and maintain hydrogen concentration in the water. For the best results, it’s crucial to choose a high-quality, certified bottle that ensures safety, durability, and effective hydrogen production.

Find the best hydrogen water bottles at our website to enjoy the full benefits of hydrogen-rich water.

FAQs

- Can you use tap water in a hydrogen water bottle?

Yes, but using filtered or distilled water is better for optimal hydrogen production and to prevent scaling on the electrodes.

- How do I know if my hydrogen water bottle is working?

Check for LED indicators or bubbles in the water during electrolysis. Some bottles have built-in hydrogen concentration meters for confirmation.

- What is the lifespan of a hydrogen water bottle?

Typically, 2 to 3 years with regular use and proper maintenance. Key components may need replacement over time.

- How do you maintain a hydrogen water bottle?

Regularly clean the bottle, replace filters or membranes as needed, and keep the battery charged. This ensures consistent performance and extends the bottle’s life.